PTI

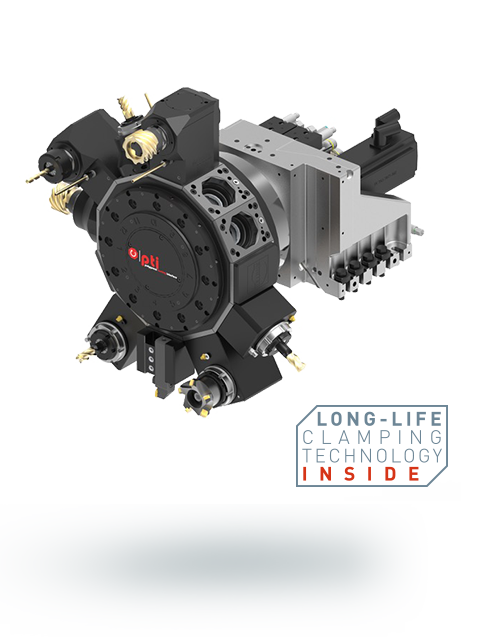

THE STANDARDISED TURNING INTERFACE

The PTI (Polygonal Turning Interface) is an innovative tool interface that raises the state of the art to a whole new level and allows for standardisation in turning machine revolvers. The main design feature of the interface is its eight-sided polygonal taper with flush fitting.

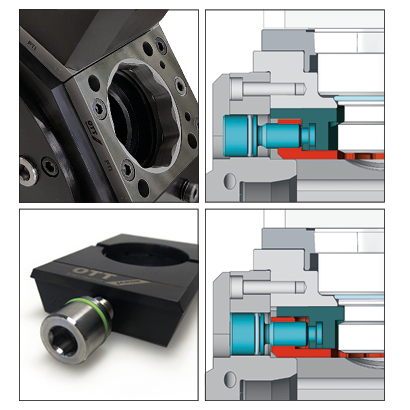

With the PTI system, static and driven tools are clamped using OTT-JAKOB’s quick-clamping system. The interface has holes for coolant and sealing air. An interface for data and energy transfer is also provided, so that the PTI can also be integrated in Industry 4.0 environments. The PTI is available in sizes PTI42, PTI54 and PTI65.

The PTI was developed as part of a joint research project in which OTT-JAKOB was a major participant. The ultimate objective is to standardise the shaft, holder and coupling. The steps necessary for this are current ongoing after a successful market launch. For further information visit pti-interface.com.